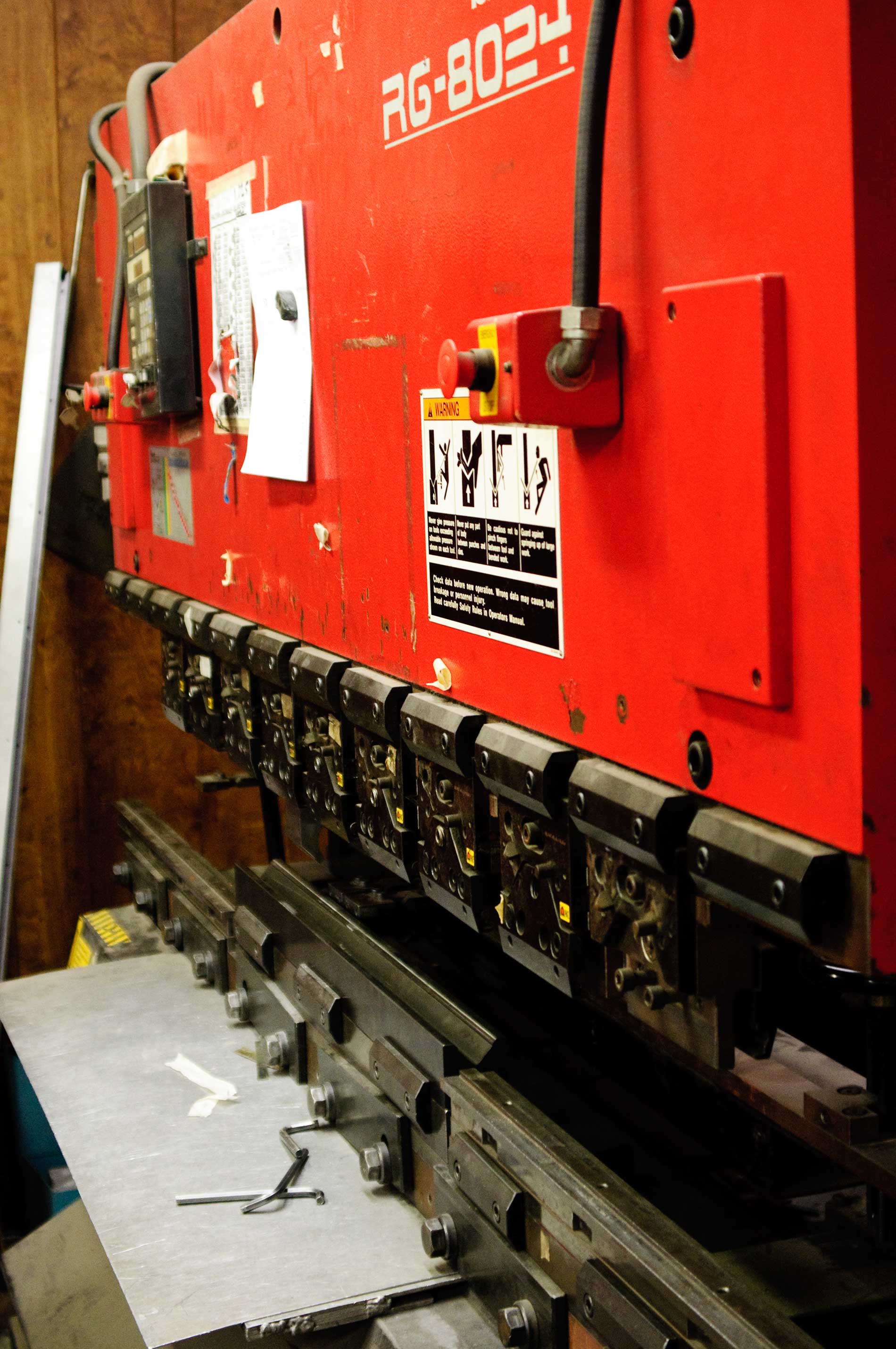

CNC PUNCHING

Computer numerically controlled (CNC) punching is a sheet metal manufacturing process that is carried out by CNC punch presses.

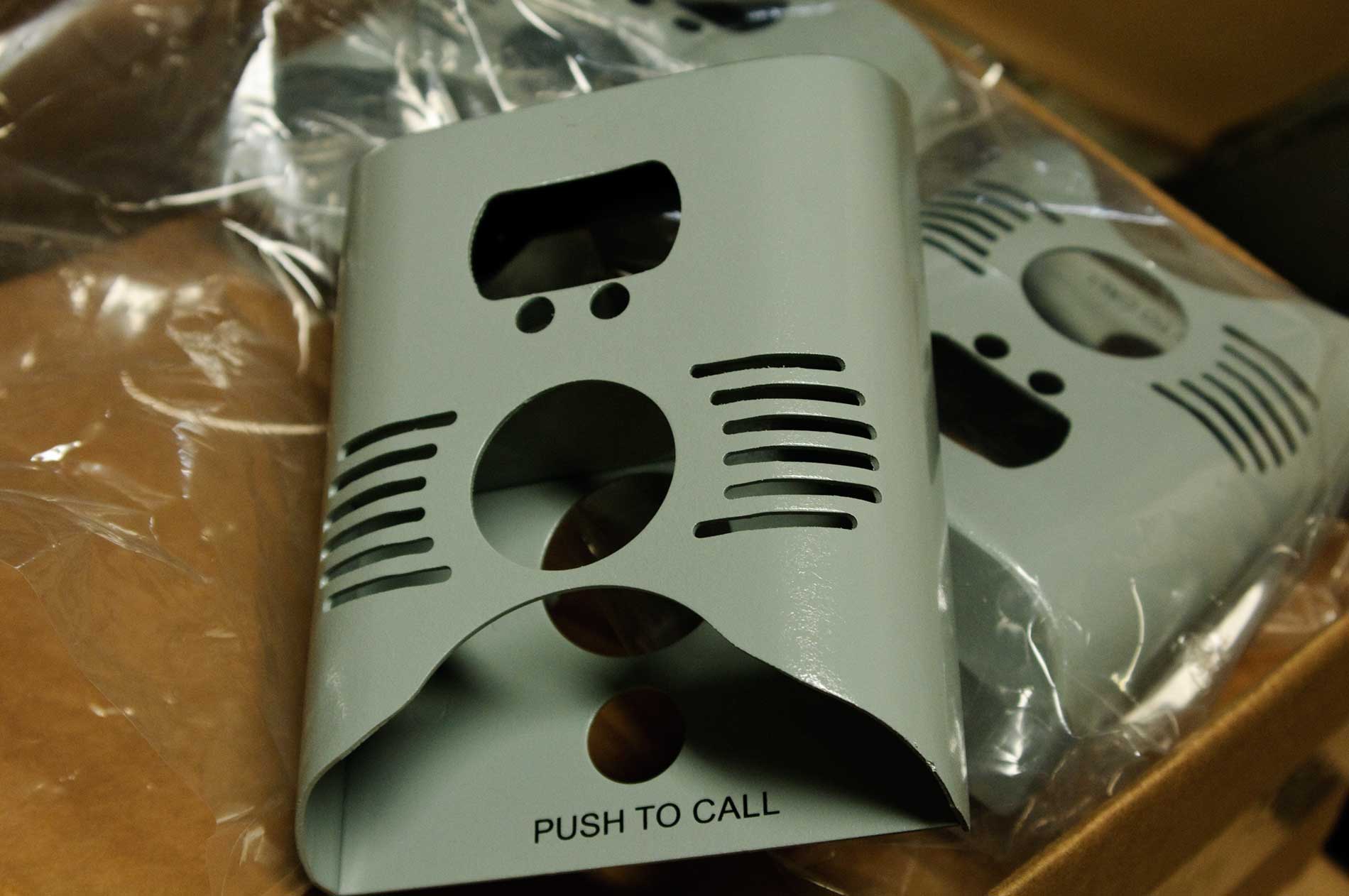

is a family run sheet metal fabrication company manufacturing sheet metal work and precision presswork for the lighting, heating, electronics, audio and similar industries. We offer comprehensive sheet metal fabrication services, including advice on sheet metal work designs for manufacturing, sub-assembly work and treatments or finishes to your own drawing specification.

Computer numerically controlled (CNC) punching is a sheet metal manufacturing process that is carried out by CNC punch presses.

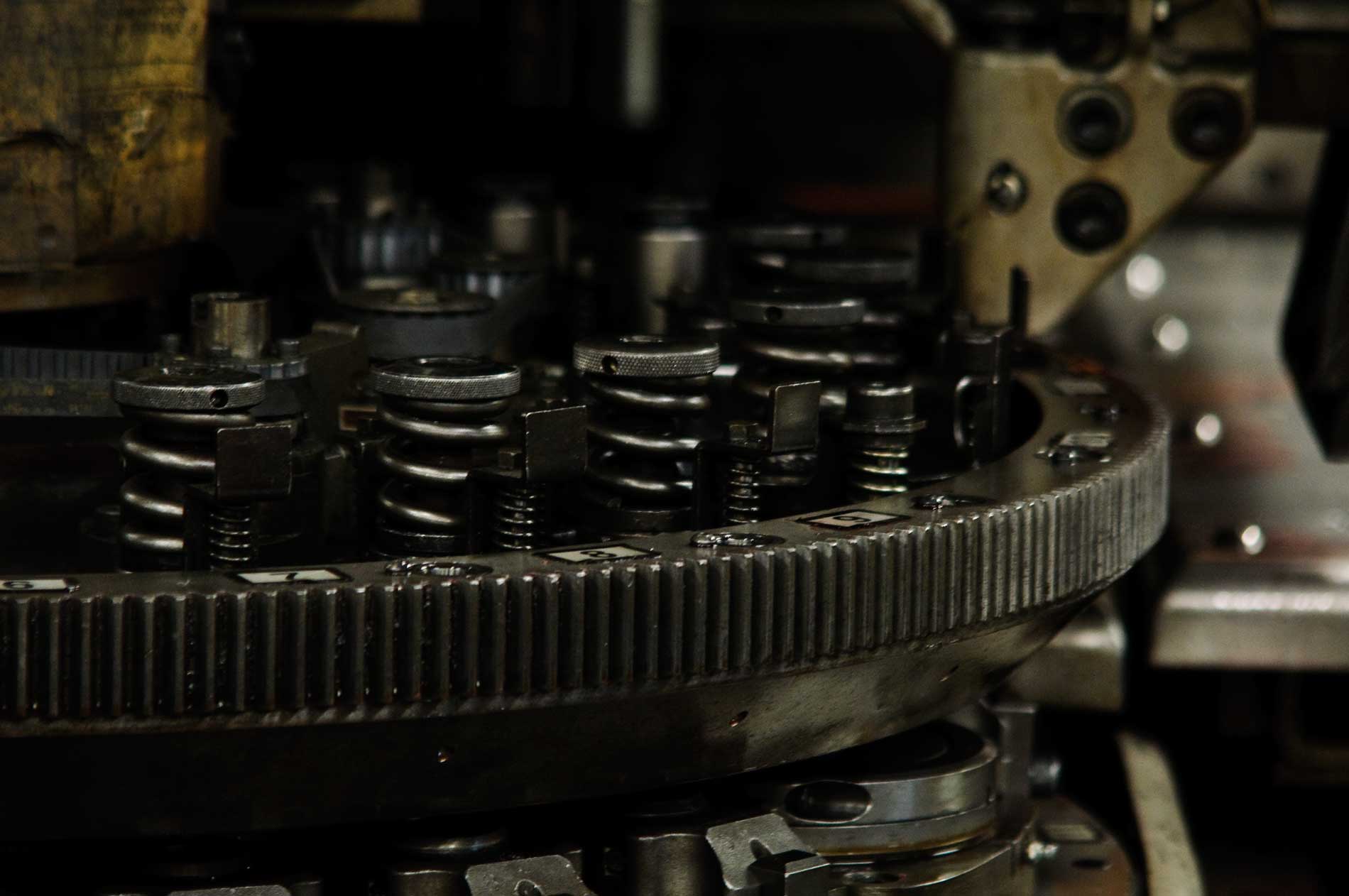

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece.

Sheet metal rolling passes metal stock through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. Notching is a metal-cutting process used on sheet-metal or thin bar-stock.

Remove burrs from sheared or punched metal sheets as part of the production process

Sheet metal finishing techniques we offer include metal plating, buff polishing, powder coating and sand blasting.

When a sheet metal fabricated component has two or more gauges of sheet metal in its design, spot welding techniques enable you to bring these parts of sheet metal together into one fabrication assembly.

We pride ourselves on our flexibility to offer you the complete sheet metal fabrication service from design to manufacturing. Why not let us look at your sheet metal work requirements today!

The key to quick estimates is the ability to bring together all necessary manufacturing material costs, machine process and labor times

Our software tracks your job through every design and production step.

3D software models of complex sheet metal fabrications and full working assemblies can be generated to help eliminate design errors before any sheet metal work is undertaken.

Comprehensive sheet metal fabrication services from design to shipping

We will work with your needs to guarantee delivery of your components at the precise time you need - no expensive inventory waiting in boxes.

Every job is subject to quality control review at each major production step, guaranteeing you zero defect products.

It isn't surprising, there are probably a million things you have to ask!

Feel free to contact us with this form, or for more detailed questions, click here.

@farrellprecision.com