Capabilities

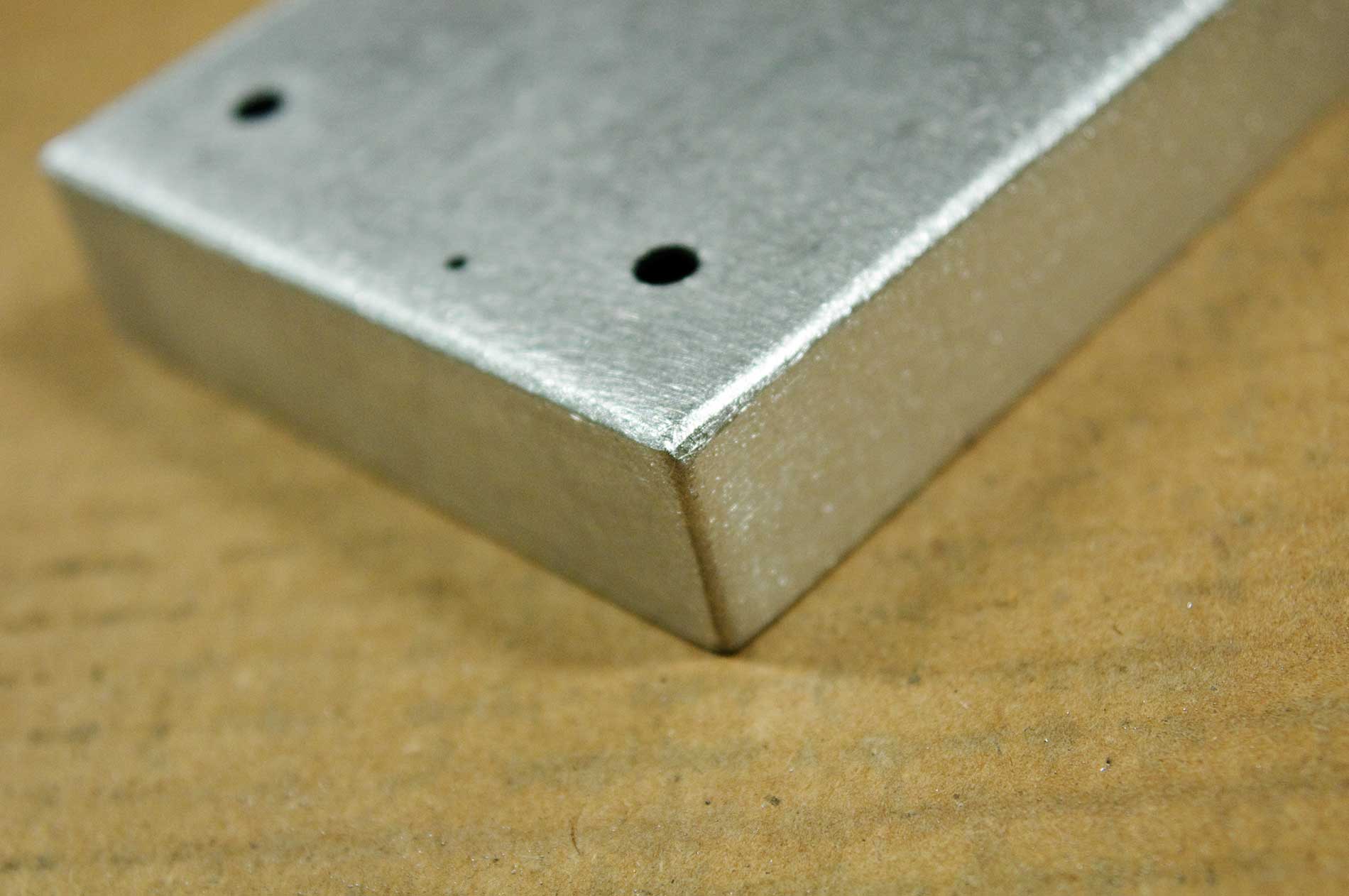

Our precision sheet metal fabrication means we stamp or fabricate sheet metal exactly how you need it, when you need it: any thickness, any tolerance, any quantity, we work with ferrous and non-ferrous materials of all types and sizes including carbon steel, copper, titanium, and other alloys.

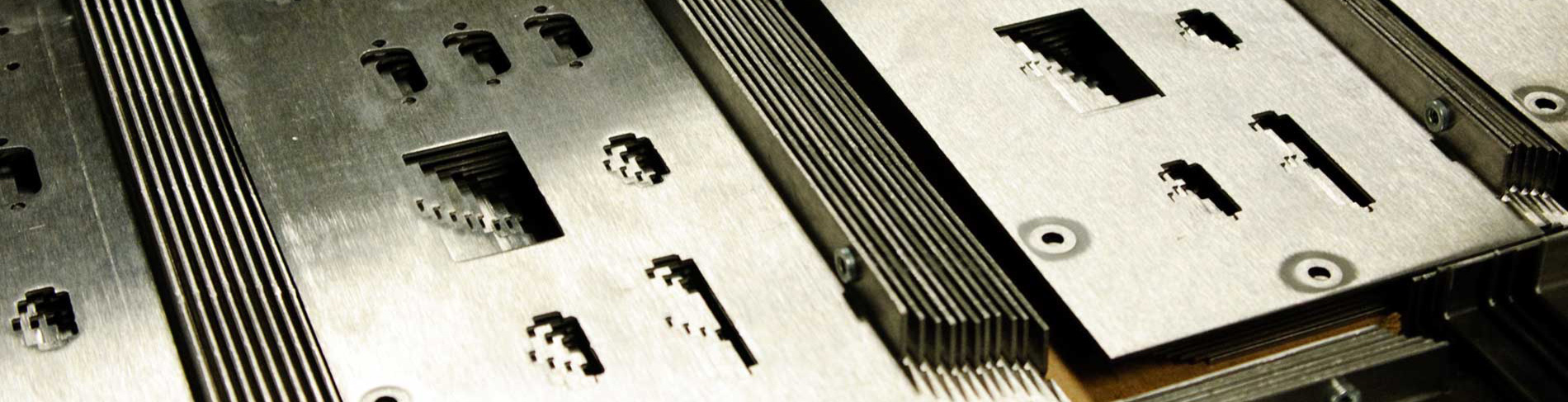

Computer numerically controlled (CNC) punching is a sheet metal manufacturing process that is carried out by CNC punch presses.

Sheet metal rolling passes metal stock through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. Notching is a metal-cutting process used on sheet-metal or thin bar-stock.

The most common sheet metal cutting processes are performed by applying a shearing force.

When a sheet metal fabricated component has two or more gauges of sheet metal in its design, spot welding techniques enable you to bring these parts of sheet metal together into one fabrication assembly.

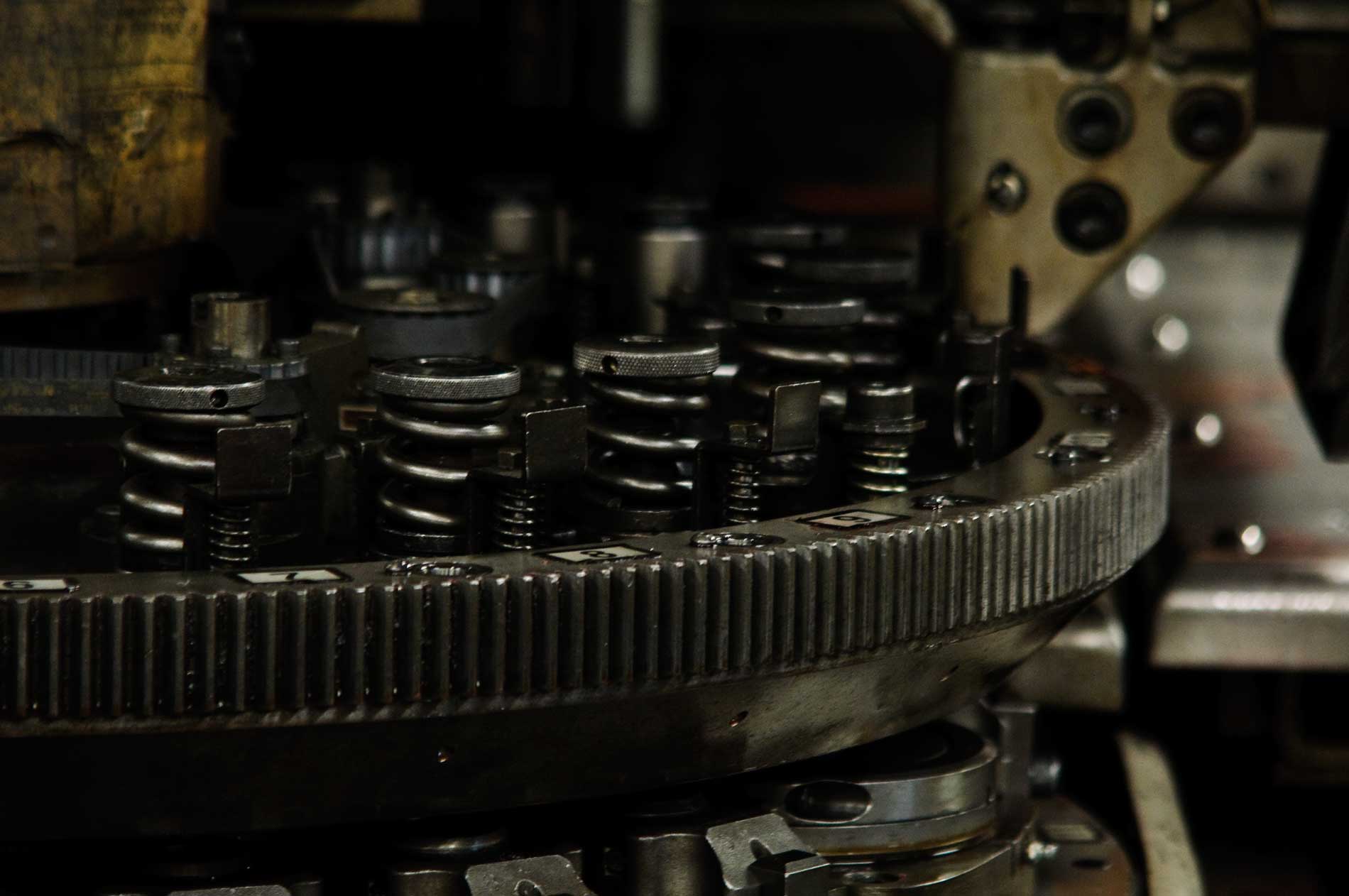

CNC milling parts are the most commonly used machining process. It is the process that removes the material from a workpiece by using rotary cutters. CNC milling machines are often classified by the number of axes that they have. The axis for horizontal movement are called X and Y, and the axis for vertical movement is called Z.

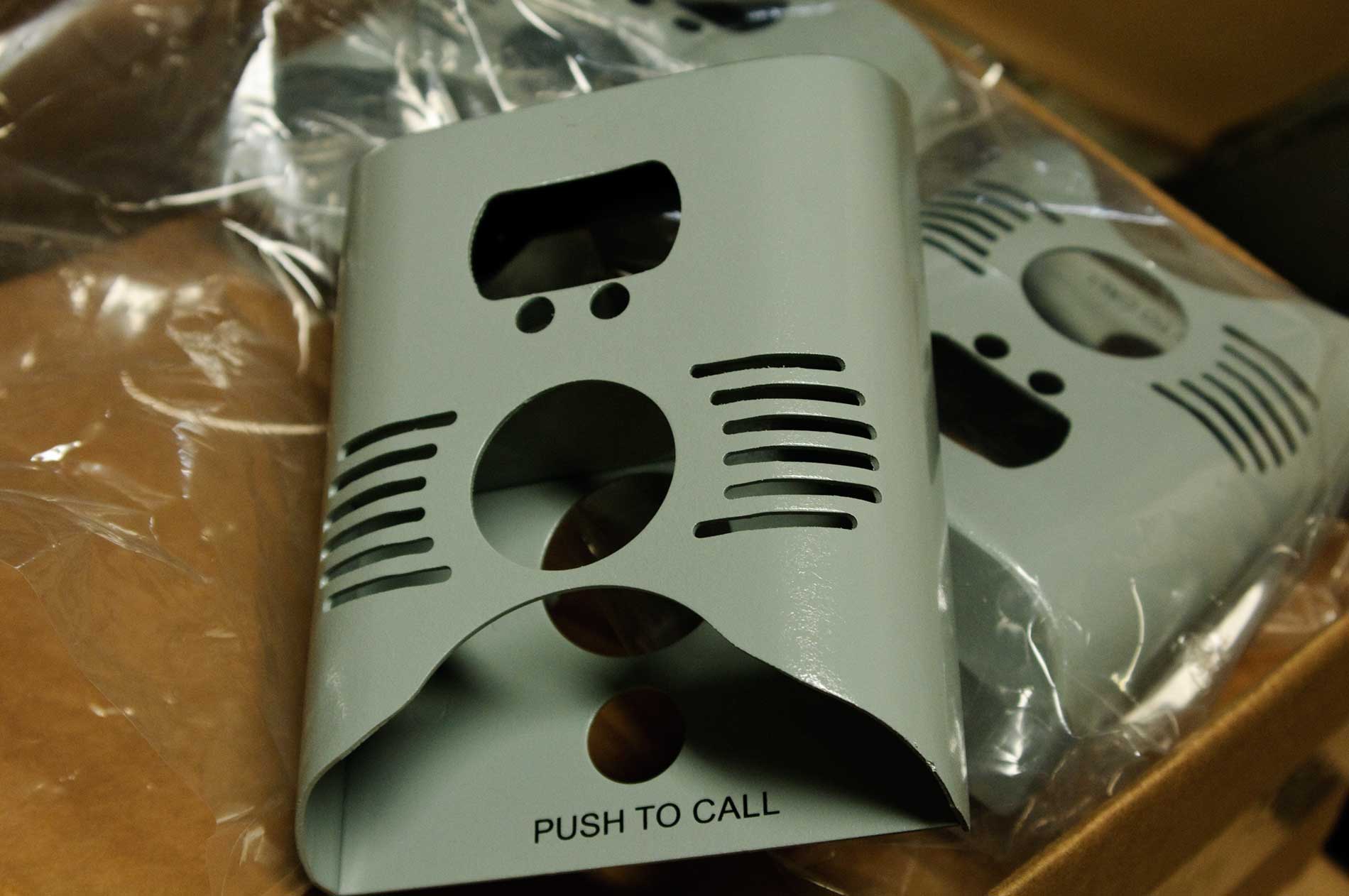

Sheet metal finishing techniques we offer include metal plating, buff polishing, powder coating and sand blasting.

| Capabilities List | |

|---|---|

| CNC PUNCHING | ROLLING & NOTCHING |

| SHEARING | WELDING & SPOT WELDING |

| MILLING | METAL FINISHING |

| DEBURRING | SAWING |

| PROGRAMMING & TRACKING | MATERIAL HANDLING |

Equipment

This is a list of the major tools that we use, excluding granite and steel surface plates, various micrometers, indicators, plug gages, thread gages, ring gages, dial bore indicators, calipers, etc.

| Equipment List | |

|---|---|

CNC PUNCHING |

ROLLING & NOTCHING |

| 2002 Strippit Fabri-Center 1000-20 | Heller WSW 50 Universal Ring Roller |

| 2003 Strip pit Fabri-Center 1000-XP | Pexto roller 383D |

| 2005 Strip pit Fabri-Center 1000-XP | Kidder Hydraulic Roller |

| Strippit NC Control AG 1830 | Power Notcher |

SHEARING |

BAND SAWS |

| Allsteel 10 ft, 10 Gauge w/Programmable back gauge | 2007 Power Horizontal Band Saw |

PRESS BRAKES |

DRILL PRESS/LATHE |

| 2004 Amada 8ft 90 Ton 3 Axis | 3-Delta Bench Model Drill Press |

| 2004 Amada 8ft 90 Ton 2 Axis | Hardinge Chucker Lathe |

| Chicago 8ft 55 Ton w/CNC BIG | Econo 14" Lathe |

WELDING |

SPOT WELDING |

| 2-Miller Syncrowave 300 | 2008 Amada Aluminum Spot welder |

| 2-Miller Syncrowave 250 | Scaicky 50 KVA 18" Throat w/lA Electric Tuner |

| Lincoln Wirematic 250 Mig | Electric Spot Welder 5 KWA Cap. |

| Oxygen Acetylene | METAL FINISHING |

MILLING |

200 8'x8'x8' Powdercoat Booth |

| 4-Bridgeport Milling Centers | 2 Binks 8'x8'x8' Paint Spray Booths |

| Bridgeport Miller wi Summit Bandit 3 Axis CNC Control | 2007 Weisman 4'x4'x8' Paint Oven |

PROGRAMMING & TRACKING |

2007 Weisman 6'x6'x8' Paint Oven |

| SoliWorks 2018 Professional | HARDWARE INSTALLATION |

| Metalsoft, FabrWin Programming | 2004 Haegar Auto-Feed Model 8-24 |

| E2 Shop Tech Job Tracking w/barcode scanning | Haegar Manual-Feed Model 6-18 |

MATERIAL HANDLING |

|

| 2008 TCW 3 Ton Highlift-Forklift | |